Në një përparim që konsiderohet një moment kyç për aviacionin e qëndrueshëm, një koalicion inxhinierësh të aeronautikës dhe shkencëtarësh të materialeve ka arritur të tejkalojë një sfidë trefishe inxhinierike që kishte bllokuar zhvillimin e aeroplanëve me hidrogjen për mbi një dekadë.

Hidrogjeni — i parë si alternativa e pastër ndaj karburanteve fosile — ka premtuar prej kohësh fluturim pa emetime. Megjithatë, për shkak të tre problemeve të lidhura ngushtë, përdorimi i tij në avionët komercialë ishte i pamundur: magazinimi i karburantit, siguria kriogjenike dhe efikasiteti i propulsionit. Tani, një triadë revolucionare inovacionesh duket se ka zgjidhur kodin.

Problemi Trefishtë

Avionët me hidrogjen kërkojnë ruajtjen e karburantit në temperatura jashtëzakonisht të ulëta — rreth -253°C — për ta mbajtur atë në gjendje të lëngshme, e cila është e nevojshme për të magazinuar energji të mjaftueshme në një enë të lehtë. Por kjo sjell tre sfida kryesore:

- Dendësia e magazinimit volumetrik: Hidrogjeni lëng zë më shumë hapësirë se karburanti për avionë. Rezervuarët ekzistues ishin ose shumë të mëdhenj ose shumë të rënda për fluturim.

- Integriteti dhe siguria kriogjenike: Mbajtja e hidrogjenit në temperatura ultra-të ftohta pa rrjedhje ose dështime katastrofike paraqiste rreziqe serioze, veçanërisht në lartësi prej 35,000 këmbësh.

- Efikasiteti i propulsionit me hidrogjen: Turbinat kishin vështirësi për të arritur të njëjtin shtytje dhe efikasitet si me karburantet konvencionale, veçanërisht në lartësi dhe klimë të ndryshme.

Zgjidhja e njërit prej këtyre problemeve individualisht do të kishte shënuar përparim. Por zgjidhja e të treve së bashku — në një sistem mjaft të lehtë për fluturim dhe mjaft të sigurt për pasagjerët komercialë — dukej pothuajse e pamundur. Deri tani.

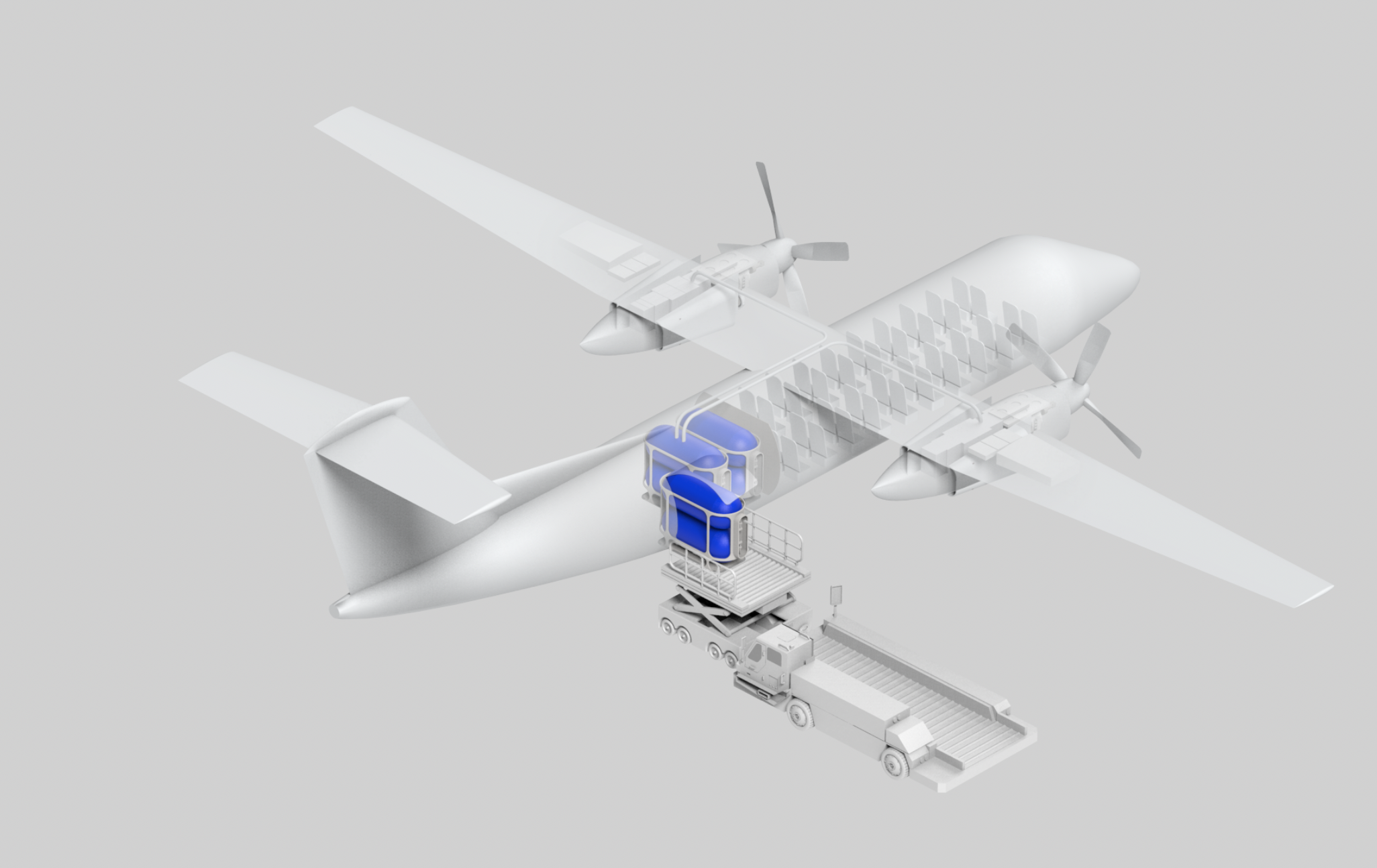

Përparimi #1: Rezervuarët Kriogjenikë të Forcuar me Graphene

Nën drejtimin e një ekipi materiali nga DLR Aerospace Center në Gjermani, studiuesit zhvilluan rezervuarë kompozitë të forcuar me graphene që janë 30% më të lehtë dhe 50% më rezistentë ndaj temperaturës se alternativat me fibra karboni. Këta rezervuarë minimizojnë humbjet nga avullimi, reduktojnë nevojën për izolim dhe përballojnë diferencat e presionit pa lodhje strukturore — të gjitha këto duke u përshtatur në trupin standard të një avioni narrow-body.

Përparimi #2: Sistemi Inteligjent i Menaxhimit Kriogjenik

Për të menaxhuar hidrogjenin në temperatura kriogjenike, një kompani franceze e avionikës krijoi një sistem vetërregullues kriogjenik të fuqizuar me AI. Ai rregullon në mënyrë dinamike presionin, rrjedhën e izolimit dhe ventilimin bazuar në lartësi, temperaturën e jashtme dhe fazën e fluturimit. Më e rëndësishmja, integron një protokoll emergjence për fikje të shpejtë dhe ventilim, duke zgjidhur një nga pengesat kryesore të sigurisë.

Përparimi #3: Turbinat Hibrid Hidrogjen-Elektrik

Një ekip në MIT, në bashkëpunim me Rolls-Royce, zhvilloi turbofan-in e parë hibrid hidrogjen-elektrik, i aftë të kalojë midis djegies së pastër të hidrogjenit dhe shtytjes elektrike në varësi të kërkesës. Ky zhvillim jo vetëm që përmirëson efikasitetin gjatë ngritjes dhe ngjitjes (faza më intensive në karburant), por gjithashtu redukton ndjeshëm emetimet e oksidit të azotit (NOx).

Gati për Fluturim deri në 2029

Sistemi i integruar zhvilloi fluturimin e tij të parë të suksesshëm muajin e kaluar në një Airbus A320 të përshtatur, duke arritur një fluturim 1.5-orësh pa emetime, me 10% karburant të mbetur. Programi i financuar nga BE-ja, i quajtur HYRIZON, planifikon testime të mëdha për vitin 2026, me synim certifikimin deri në vitin 2029.

Reagimi i Industrisë

CEO i Airbus, Guillaume Faury, e quajti këtë përparim “një pikë kthesë” për aviacionin. “Kjo nuk është vetëm një sukses inxhinierik — është një rrugë drejt fluturimit të qëndrueshëm afatgjatë brenda dekadës,” tha ai.

Grupet mjedisore gjithashtu mirëpritën lajmin, megjithëse paralajmërojnë që prodhimi i hidrogjenit duhet të jetë i gjelbër. Aktualisht, shumica e hidrogjenit prodhohet nga gazi natyror. Po punohet për të zgjeruar prodhimin e hidrogjenit të gjelbër përmes elektrolizës me energji diellore dhe era.

E Ardhmja e Fluturimit

Me zgjidhjen e problemit trefishtë, analistët besojnë se avionët komercialë me hidrogjen mund të bëhen realitet brenda 10–15 viteve të ardhshme. Linjat ajrore si Lufthansa dhe Emirates kanë nënshkruar tashmë marrëveshje paraprake për adoptim të hershëm.

Fluturimi me hidrogjen mund të mos jetë ende mainstream — por tani nuk është më një ëndërr e shtyrë nga fizika e pamundur. Është një e ardhme që po ndërtohet, rezervuar pas rezervuari, turbinë pas turbina, fluturim pas fluturimi.