Seria TeSys™ Deca Motor Control është një gamë moderne produktesh për kontrollin e motorëve, e projektuar për të ofruar besueshmëri të lartë, fleksibilitet dhe performancë në aplikime industriale. Kjo seri mbulon një gamë të gjerë nevojash, duke përfshirë nisjen, kontrollin dhe mbrojtjen e motorëve, duke garantuar funksionim efikas dhe siguri të shtuar. Më poshtë gjeni një përshkrim të detajuar të komponentëve kryesorë, veçorive dhe përfitimeve.

Komponentët Kryesorë

Kontaktorë

Funksioni:

Komandojnë dhe kontrollojnë motorët elektrikë, duke siguruar operacione të buta nisje/ndalimi.

Specifikime:

- Të disponueshëm në rryma nga 6 A deri në 1800 A, për aplikime AC dhe DC.

- Tensione bobine: gamë e gjerë duke përfshirë 24V, 48V, 110V dhe 230V (AC/DC).

- Kasa kompakte për optimizim maksimal të paneleve elektrike.

Veçori:

- Bobina me konsum të ulët energjie për reduktim të kostove operative.

- Kontakte ndihmëse të integruara për lidhje me qarqet e komandimit.

- Qëndrueshmëri e lartë elektrike dhe mekanike (deri në 10 milion operacione).

Aplikime:

Pompë, kompresorë, transportues (conveyors) dhe sisteme HVAC.

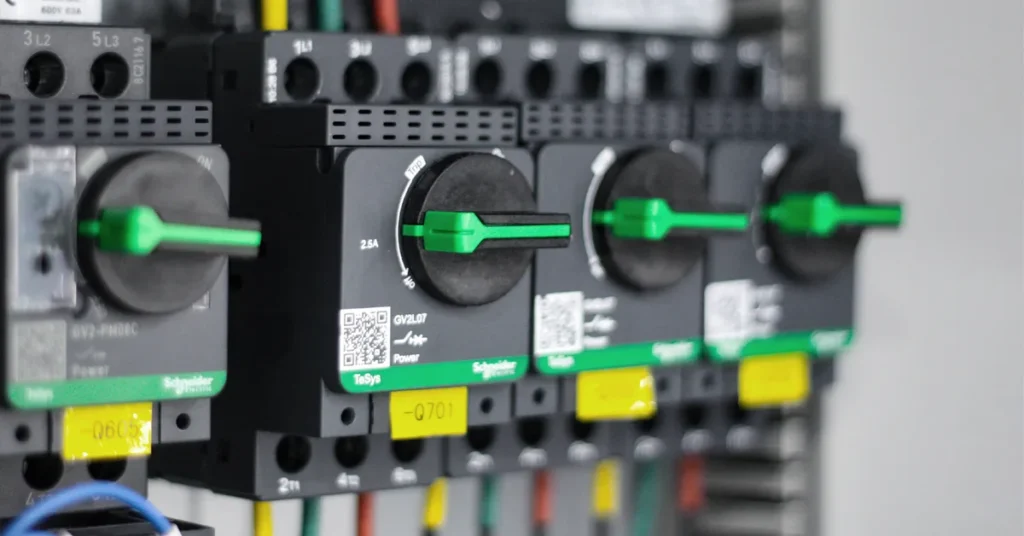

Starterë Manualë për Motorë (MMS)

Funksioni:

Sigurojnë nisje direkte të motorit (DOL) me mbrojtje të integruar ndaj mbingarkesës dhe qarkut të shkurtër.

Specifikime:

- Gamë rryme: 0.1 A – 100 A, për motorë të madhësive të ndryshme.

- Kapacitet ndërprerjeje deri në 100 kA.

- Rregullim termik i mbingarkesës për mbrojtje të personalizuar të motorit.

Veçori:

- Dizajn kompakt dhe modular për integrim të lehtë në panele.

- Dorezë rrotulluese me tregues të qartë ON/OFF për përdorim të sigurt.

- Aksesorë opsionalë: kontakte ndihmëse, çlirim nëntensioni dhe shunt trip.

Aplikime:

Makineri të vogla, sisteme transportuese dhe pajisje të pavarura me motor.

Rele Mbingarkese

Funksioni:

Mbrojnë motorët nga mbinxehja e shkaktuar nga mbingarkesa e zgjatur ose bllokimi i motorit.

Specifikime:

- Gamë rryme: 0.1 A – 630 A.

- Klasa shkëputjeje: Class 10, 20 ose 30, sipas nevojës së aplikimit.

- Rregullator i saktë për vendosjen e mbingarkesës.

Veçori:

- Opsione rivendosjeje manuale ose automatike.

- Instalimi i drejtpërdrejtë “clip-on” mbi kontaktorët TeSys™.

- Dizajn kompakt për kursim hapësire.

Aplikime:

Motorë për ventilatorë, miksera, pompa dhe makineri industriale.

Veçori dhe Përfitime Kryesore

Performancë dhe Besueshmëri

- Projektuar për ambiente industriale të vështira, me stabilitet të lartë termik dhe qëndrueshmëri mekanike.

- Testuar sipas standardeve ndërkombëtare (IEC 60947, UL, CSA).

Efiçencë Energjetike

- Bobina me konsum të ulët energjie në kontaktorë dhe MMS.

- Dizajn i optimizuar për shpërndarje minimale të nxehtësisë në panele.

Dizajn Kompakt dhe Modular

- Kursim hapësire në panele elektrike.

- Aksesorë modularë që lehtësojnë përmirësimet dhe reduktojnë kohën e mirëmbajtjes.

Mbrojtje e Avancuar

- Mbrojtje ndaj mbingarkesës dhe qarkut të shkurtër e integruar në MMS.

- Rregullime fleksibile për përshtatje sipas karakteristikave të motorit.

Lehtësi në Përdorim dhe Mirëmbajtje

- Lidhje “plug-and-play” për instalim të shpejtë.

- Tregues vizualë dhe opsione rivendosjeje për diagnostikim të thjeshtë.

Përputhshmëri Globale

- I certifikuar për përdorim në tregje ndërkombëtare.

- Kompatibilitet universal me sisteme të ndryshme kontrolli dhe protokolle komunikimi.

Aplikime

Seria TeSys™ Deca Motor Control përdoret gjerësisht në industri të ndryshme, si:

- Prodhim: Sisteme transportuese, linja montimi dhe robotikë.

- Trajtimi i Ujit: Stacione pompimi dhe sisteme filtrimi.

- Energji: Sisteme të energjisë së rinovueshme dhe integrim në rrjet.

- HVAC: Ventilatorë, kompresorë dhe chiller-a.

Përzgjedhja e Produkteve dhe Mbështetja

Schneider Electric ofron mjete të avancuara për përzgjedhjen e produkteve, si konfiguratorë online dhe dokumentacion teknik të detajuar. Rrjeti i tyre global i mbështetjes siguron asistencë për komisionim, diagnostikim dhe optimizim të sistemeve të kontrollit të motorëve.