As the aviation industry faces increasing pressure to reduce carbon emissions and improve fuel efficiency, aerospace leaders like Airbus are turning to innovative propulsion systems to meet the challenges of tomorrow. One of the most promising and radical solutions under development is the open rotor engine—a concept that has resurfaced with new momentum thanks to advanced materials, aerodynamics, and a renewed focus on sustainability.

Airbus, in collaboration with major engine manufacturers and through its long-term commitment to cleaner skies, is at the forefront of reviving and reimagining open rotor technology. With the potential to dramatically cut fuel consumption and emissions, open rotor engines could power the next generation of eco-efficient aircraft.

What Is an Open Rotor Engine?

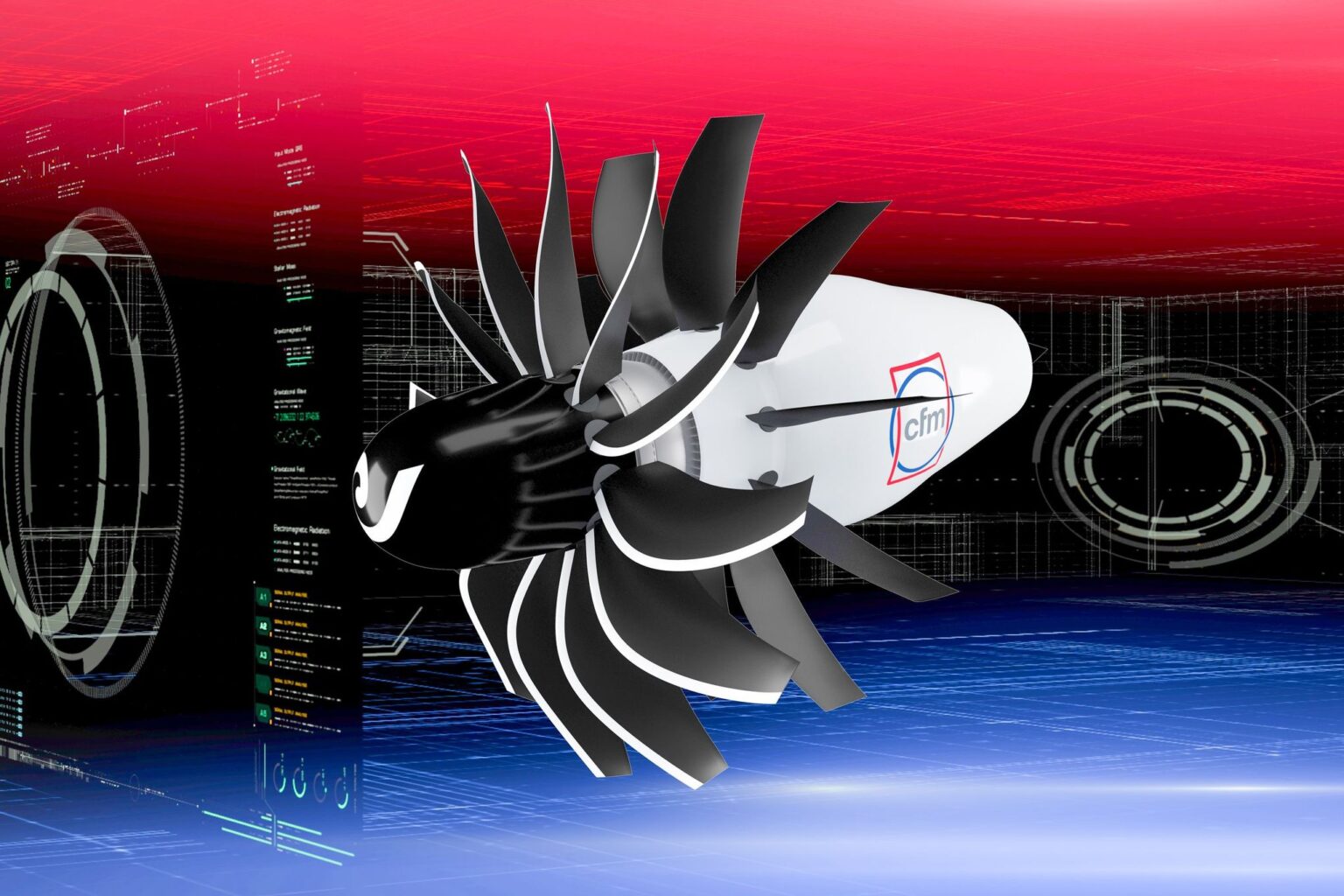

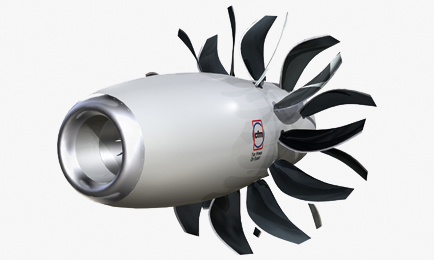

An open rotor engine—also known as an unducted fan engine—is a type of jet engine that uses large, unshrouded, counter-rotating fan blades to generate thrust. Unlike conventional turbofan engines, which encase the fan in a nacelle, the open rotor exposes the blades to open air, reducing weight and increasing the engine’s bypass ratio significantly.

Bypass ratio refers to the amount of air bypassing the engine core compared to the amount going through it. Open rotor engines can achieve extremely high bypass ratios (above 30:1), compared to modern turbofans (around 10:1), which translates into better fuel efficiency and lower carbon emissions.

The Airbus Vision and Collaboration with CFM

Airbus is actively exploring open rotor propulsion through its partnerships, particularly with CFM International, a joint venture between GE Aviation and Safran Aircraft Engines. In 2021, CFM launched the RISE (Revolutionary Innovation for Sustainable Engines) program, which includes the development of a demonstrator open rotor engine. Airbus is collaborating with CFM to evaluate how this new engine architecture could integrate with future aircraft designs.

Key goals of the RISE program include:

- 20% improved fuel efficiency compared to current LEAP engines.

- Compatibility with 100% Sustainable Aviation Fuel (SAF) and hydrogen-based fuel.

- Noise reduction technologies to meet future acoustic standards.

Design Features of the Open Rotor Engine

Airbus and its partners are designing open rotor systems with the following characteristics:

- Counter-Rotating Blades: Two sets of large fan blades rotate in opposite directions to increase thrust and reduce swirl losses.

- Geared Fan Systems: Advanced gearboxes optimize rotational speeds for efficiency.

- Lightweight Materials: Carbon fiber composites and titanium-aluminide reduce engine weight while enhancing performance.

- Noise Reduction: Innovative blade shapes, active noise cancellation systems, and precise blade synchronization mitigate one of the main challenges of open rotors—noise.

Flight Testing and Timeline

CFM and Airbus plan to begin flight testing the open rotor demonstrator around 2025–2026, using an Airbus A380 as a flying testbed. This will allow engineers to evaluate the engine’s real-world performance, acoustics, and integration with aircraft structures.

While open rotor technology is unlikely to appear on commercial jets before the early 2030s, it is being seriously considered for the next generation of single-aisle aircraft, which will replace today’s A320neo and Boeing 737 MAX families.

Benefits of Open Rotor Engines

- Fuel Efficiency: Up to 20–30% reduction in fuel consumption compared to current turbofan engines.

- Lower CO₂ Emissions: Significant decrease in lifecycle emissions, especially when combined with SAF or hydrogen.

- Future-Ready: Designed to be compatible with evolving propulsion technologies and clean fuels.

- Reduced Operating Costs: Improved fuel burn translates to lower airline expenses over time.

Challenges Ahead

While promising, open rotor engines must overcome a few significant challenges:

- Noise: Exposed fan blades produce more noise than enclosed turbofans, requiring advanced mitigation.

- Integration: Requires redesign of aircraft fuselage and wing placement to accommodate the larger, rear-mounted engines.

- Public Perception: Educating the public about the safety and performance of unconventional-looking engines will be key.

A Bold Step Toward Decarbonized Aviation

The open rotor engine represents a game-changing leap in aircraft propulsion. Airbus, with its focus on innovation, sustainability, and collaboration, is leading the charge to bring this technology to the skies. While there is still work to be done, the potential benefits of open rotor systems—efficiency, reduced emissions, and compatibility with future fuels—make them a vital part of aviation’s journey toward net-zero.

As the world demands cleaner, smarter transportation solutions, open rotor engines may soon transform the way we fly—ushering in a new era of sustainable aviation.